The Level weighing mixer adopts an all-Chinese interface, which displays the working state of ingredients graphically and dynamically, and displays the weight of materials in the measuring hopper digitally, which is suitable for the operating habits and knowledge level of operators. Almost all the operation buttons can be clicked on the screen by the mouse, which improves the production efficiency and reduces the labor intensity of workers. Through the Ethernet in the production site, the batching computer in the production site can be networked with the office computer, and the production output statistics and raw material consumption assessment can be paperless. Data can be saved indefinitely.

020-34563445

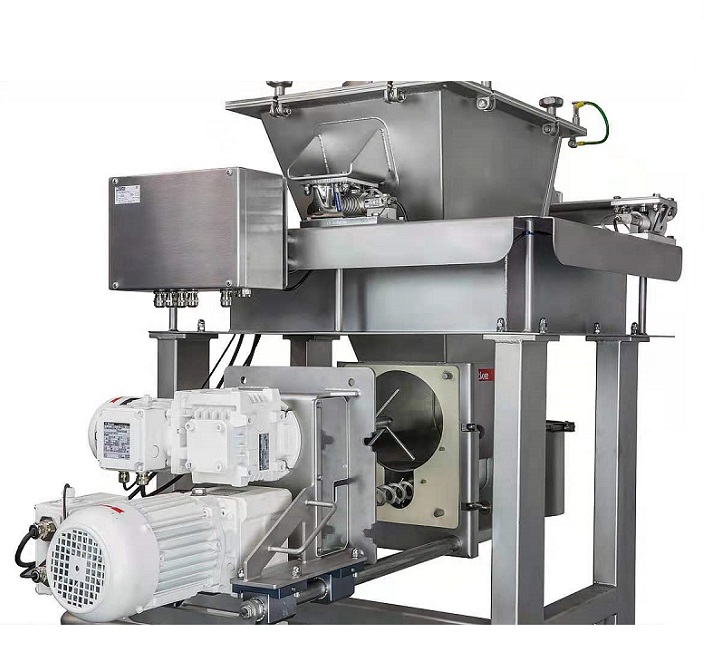

020-34563445The horizontal weighing mixer is a production equipment used in industry for automatically proportioning and processing different powder or liquid materials in a certain proportion. It is usually composed of a Weighing system, weighing control instrument, PLC system and upper computer, etc.

The weighing and mixing system includes various equipment such as the raw material storage body, conveying body, weighing and batching body, dust removal body, and material mixture.

The batching method can be reasonably selected based on the characteristics of the industry, the requirements of the production process, and the specific properties of the materials, such as "incremental" or "subtractive" weighing methods. It has multiple working modes including single-bucket single-material, single-bucket multi-material, and multi-bucket multi-material.

The process flow of the weighing control system

1. The material enters the electric arc valve from the silo and is then sent into the weighing module by the screw Feeder. The weighing module measures the flow rate and adjusts the speed of the screw feeder according to the actual required flow rate, thereby achieving normal feeding.

2. After being measured by the weighing module, the powder enters the feeding box of the screw pneumatic conveying pump and is pushed forward through the feeding mechanism.

3. The powder enters the mixing chamber and is vaporized by the air at the fan outlet, and is then sent to the conveying pipeline.

The screw feeder plays a role in quantitative flow stabilization. The weighing module can not only measure the flow rate of pulverized coal but also detect whether there is a shortage of pulverized coal in the system. The screw pneumatic conveying pump not only locks the air but also conveys the materials.

It adopts advanced batching weighing instruments, which can conveniently complete high-speed communication with the PLC system through communication methods such as ProFibus, MOD-BUS, and Ethernet network. It features strong real-time performance, good reliability, and flexible configuration of the system.

Features of the automatic feeding system

The entire process can be controlled, monitored and recorded, enabling remote monitoring and after-sales support, thereby enhancing the management level.

2. Optimized production is achieved through integral operations and logical control of parameters such as time, temperature, energy, rotational speed, and pressure.

3. High-resolution load cells and weighing instruments are adopted, ensuring high weighing accuracy.

4. All key components are made of high-end brands, ensuring stability and reliability.

5. Open human-machine interface, multi-area display and monitoring functions during system operation, easy to operate.

6. Fieldbus operation system, Internet of Things design.

7. Automatically detect the operation status. When an abnormality occurs, provide the alarm location and suggest solutions.