The screw feeder is used for the automatic batching and weighing of materials. It conveys materials from the storage bin to the weighing bin through a screw conveyor and automatically batches them according to the set weight. The screw conveyor is the core component of the screw weighing and feeding machine, consisting of a screw shaft and screw blades rotating around it. When the motor drives the screw shaft to rotate, the screw blades will push the material from the storage bin to the discharge port, and then it will fall into the weighing bin under the effect of gravity.

020-34563445

020-34563445The screw Feeder is used for the automatic batching and weighing of materials. It conveys materials from the storage bin to the weighing bin through a screw conveyor and automatically batches them according to the set weight. The screw conveyor is the core component of the screw weighing and Feeding machine, consisting of a screw shaft and screw blades rotating around it. When the motor drives the screw shaft to rotate, the screw blades will push the material from the storage bin to the discharge port, and then it will fall into the weighing bin under the effect of gravity.

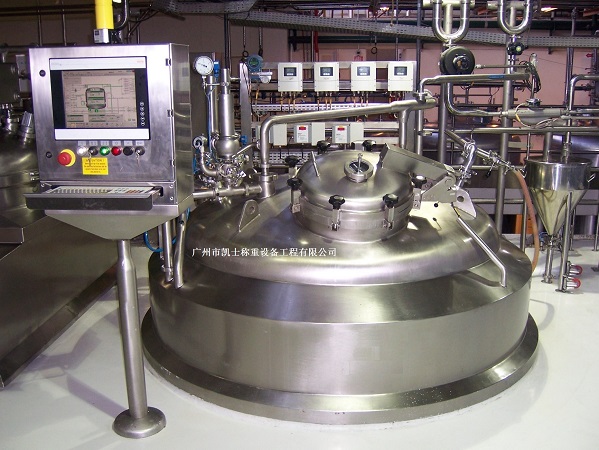

The weighing feeding machine monitors the material weight in real time through high-precision weighing sensors and controllers. By comparing the preset feeding amount with the actual data, the drive system adjusts the feeding speed to achieve precise control. Equipped with advanced control systems and software, it can automatically manage and monitor the entire feeding process, improving production efficiency and quality.

The feeding system and the hopper door are interlocked when they are fully closed. Feeding begins only when the discharge door is closed. If the hopper door cannot be fully closed within a certain period of time after the closing signal is given, the PLC will generate an alarm to prompt maintenance personnel to maintain and inspect the hopper door. During the batching process, the feeding is divided into fast feeding and slow feeding until the specified flow rate is reached. After weighing is completed, a request for unloading is made to the PLC. Once all the material doors are fully closed, the PLC allows the next type of material to be added. All controls are implemented by the PLC for interlocking control, and the PLC controls the sequential start and stop.

The weighing and feeding machine is an automated device widely used in the industrial field, mainly for precisely controlling the feeding amount of materials. It precisely weighs the materials through its internal Weighing system, which usually includes high-precision weighing sensors and weighing controllers, and can monitor the weight changes of the materials in real time during the feeding process. When materials are added to the feeding machine, the weighing module will sense the change in weight and transmit this information to the weighing controller. After receiving the signal from the weighing module, the weighing controller will process and analyze it quickly. By comparing the preset feeding amount with the actual weighing data, calculate the amount of material that needs to be added further. The calculation process is usually based on advanced control algorithms to ensure the accuracy and stability of the feeding amount.

According to the calculation results of the weighing controller, the feeding machine will adjust the feeding speed of the material through its drive system. The drive system is usually composed of a motor, a reducer and a transmission mechanism, etc. It can precisely control the rotational speed and feeding amount of the feeder according to the instructions of the controller. By adjusting the parameters of the drive system, precise control of the material feeding speed can be achieved.

The weighing and feeding machine is also equipped with an advanced control system and software, which can achieve the automatic management of the entire feeding process. The control system can set parameters such as feeding amount, feeding speed and feeding time according to production requirements, and monitor and adjust them in real time through the software interface. Meanwhile, the control system can also be linked and controlled with other equipment on the production line to achieve the automation and intelligence of the production process.