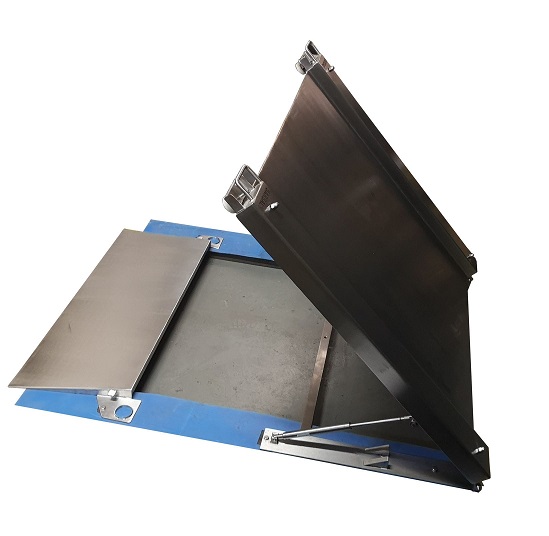

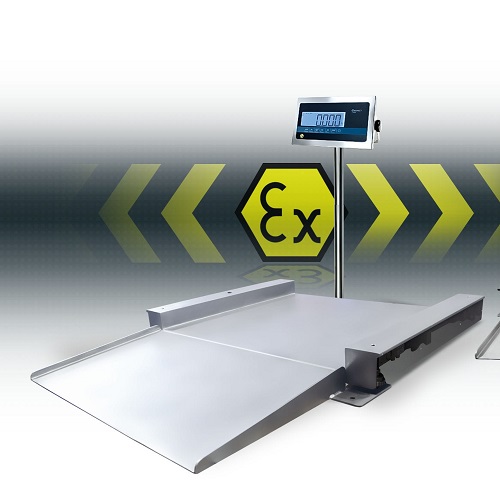

The folding electronic floor scale mainly consists of two parts: the scale body and the weighing control system. The scale body part is composed of a storage bin, feeding and loading, weighing hopper, etc. The floor scale control system is composed of a scale platform, weighing sensors, weighing instruments and control actuating elements, equipped with photoelectric position sensors and solenoid valve drive cylinders, etc. Its function is to detect the weight of moving items in real time. By comparing the directly set target value with the actual measured value, when the weighing controller of each floor scale production line is set up and the electronic scale is started to run, It can achieve automatic weighing, measurement and control of materials.

020-34563445

020-34563445An electronic floor scale is basically composed of several parts, including load cells, scale platforms, weighing instruments, junction boxes and communication protocols for the transmission of weighing instruments. The load cell converts the weight signal into the corresponding voltage signal, which is then amplified and sent to the A/D conversion circuit. Under the control of the weighing instrument, the analog voltage signal is converted into a digital quantity. This digital quantity is converted into a digital value consistent with the actual weight by the unit sheet machine program and sent to the weighing instrument display window for display. The weighing instrument monitors the keyboard and switch matrix. According to the key values collected, the program makes corresponding processing. The power supply circuit provides the working power for each part.

The platform scale is composed of multiple hollow closed platform thin-walled steel sections with square or rectangular cross-sections, four cantilever beam-type Weighing modules installed inside the hollow thin-walled steel sections, load-bearing and force-transmitting supports and junction boxes connected to the cantilever ends of the weighing modules, etc. According to the rated load of the designed floor scale and the scale platform size, the number of hollow closed rectangular cross-section thin-walled steel sections is determined. For example, if 5 pieces are needed, they are arranged in parallel and welded into a "bamboo row" shaped integral structure. Four cantilever beam-type weighing modules are installed in the hollow sections at both ends of the outermost thin-walled steel sections on both sides of the body. The loading disc at the cantilever end of the weighing module These are the four force support points of the "bamboo raft" type platform scale.

The weighing instrument serves as the lower computer to automatically weighing the walking items. The PLC, as the upper computer, is the core of the entire system. The PLC and the weighing instrument (lower computer) are connected through the RS-232C communication cable. Both parties have agreed on the serial asynchronous communication protocol and form a master-slave response relationship. The entire system is fully managed by the PLC. The PLC and touch screen are combined to serve as the upper computer. In the weighbridge system, the touch screen is used as the upper monitoring device, which can display on-site signals, issue real-time alarms and set control points. A touch screen is actually a dedicated single-chip microcomputer system that contains a CPU, memory, and bus controller inside. Its single-chip microcomputer can be connected to various types of PLCS through a serial interface to achieve serial communication.

The floor scale mainly consists of two parts: the scale body and the weighing control system. The scale body part is composed of the storage bin, feeding and loading, weighing hopper, etc. The floor scale control system is composed of a scale platform, weighing sensors, weighing instruments and control actuating elements, equipped with photoelectric position sensors and solenoid valve drive cylinders, etc. Its function is to detect the weight of moving items in real time. By comparing the directly set target value with the actual measured value, when the weighing controller of each floor scale production line is set up and the Electronic scale is started to run, It can achieve automatic weighing, measurement and control of materials.

The weighbridge adopts PLC as the main control and is equipped with a touch screen as the lower-level human-machine interface. It is connected through fieldbus to achieve data collection and control, ensuring the reliability and real-time performance of batching. It features rich functions such as process operation, monitoring, communication, alarm, management, trend, record and human-computer dialogue, as well as human-computer interaction, communication, display and storage, printing and other functions. It also has various operation-related functional interfaces such as data and graphic display, status monitoring, data input and information storage. The floor scale is equipped with a lead amount based on the speed of material weighing. When the weighing instrument detects that the weight of the material on the electronic scale has reached the set value, it will subtract the lead amount, and the weighing instrument will then close the feed valve. The lead time can be manually corrected or automatically corrected to ensure that the weighing instrument controls the electronic scale to achieve the set target value for each batching accuracy.

Specification parameters

Range specification: 1t to 3t

Accuracy grade: (Ⅲ) grade

Graduation values: 0.5kg, 1kg

Low-value alarm Settings: Users can customize the Settings

Rated overload capacity: 130%F•S

Safety factor: 200%F•S

Distance between the scale body and the instrument: ≥30 meters

Working power supply: 220V/50HZ

The operating temperature range of the sensor is -30℃ to 80℃

Scale body external dimensions: 1200×800×240 (mm)

Instrument parameters

Linearity: 0.05%F.S

Input sensitivity: 0.5uv/d

Full-scale input signal range: 0.5 to 24mV

A/D conversion speed: 20 times per second

Internal part degree: 800,000 yards

Sensor excitation power supply: Voltage: DC12V±0.3V

Maximum excitation current: 240mA