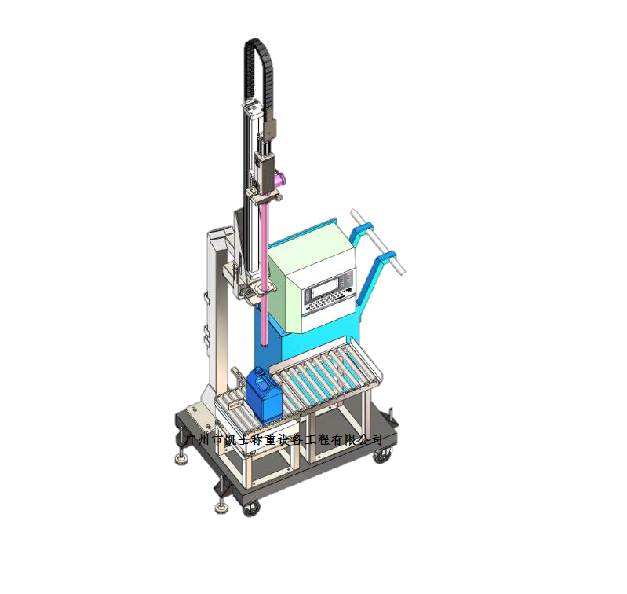

Lubricant filling machine to establish the barrel ID and information management database, in order to facilitate the data uploaded for effective query operation, filling machine feedback appropriate information in order to facilitate the implementation of the set operation. In the quantitative filling control circuit in the filling gun solenoid valve contact switch to maintain a normally closed state, after receiving the target command, start filling weighing module to display the current filling volume.

020-34563445

020-34563445When the start button is pressed, the conveyor belt of the lubricant Filling machine begins to work. Empty bottles are supplied to the conveyor belt. On the conveyor belt, the empty bottles will first pass through the empty bottle sensor detection. At this time, the empty bottle counter will be triggered to count and display the current number of empty bottles. Then, after the empty bottle positioning detection 18, the filling equipment starts to work, and the working time is determined according to the actual demand.

When the filled bottles pass through the quality sensing inspection on the conveyor belt, if they meet the quality standards, they will continue to be sent to the next stage along the conveyor belt (if they are less than the standards, the push device will be triggered to push the non-conforming products to the defective area, and then normal operation will continue). After meeting the standards, a full bottle inspection will be conducted and the count will be displayed, and the conveyor belt will continue to work.

When the packaging sealing sensor detection is passed, the packaging sealing equipment is triggered to work, processing the semi-finished products into finished products. Finally, when the liquid or water finished products run to the end of the conveyor belt and pass the end sensor detection, the mechanical baffle is triggered to operate, pushing the filled finished products on the conveyor belt into the box through rotation. When the box reaches the full box detection, the conveyor belt stops working and the loading and unloading system starts The robotic arm below transports the finished products inside the box to storage areas such as vehicles.

During the processes of filling, pushing, packaging sealing and shipping, the conveyor belt stops working and can resume operation only after the current step is completed. The empty bottle counter and the manual counter can be manually reset, and at each working stage, there will be corresponding working indicator lights to prompt.

Basic parameters

Maximum weighing capacity: 30kg

Minimum sensitivity: 0.01kg

Filling error: ±0.01-0.02kg

Filling speed: Approximately 150-180 barrels per hour for 20L

Control mode: 2-speed control

Filling method: Insertion type, liquid surface

Gun head tubing: Teflon gun head, valve + Teflon hose

Structural material: Main unit SUS304 stainless steel, conveying and palletizing carbon steel anti-corrosion paint.

Scale platform size: 400×800mm(304 stainless steel power raceway)

Empty barrel raceway: 400mm×2500mm(304 stainless steel power raceway), with an additional 1200mm slope unpowered roller

Heavy barrel raceways: 400mm×2500mm(304 stainless steel power raceways, 2 sets

Barrel separation device: Suitable for 20L barrels, carbon steel anti-corrosion paint structure, 304 stainless steel raceway.

Palletizing equipment: Translation-type, suitable for pallets of 1200×1200×140mm, including pallet, palletizing and lower pallet conveying.

Pipeline pressure: 0.2-0.6MPa(related to material properties).

Material interface: 4 DN40 flange joints, which can be customized according to the interface standards provided by the user

Air source interface: The user provides a 12mm air pipe connector for quick coupling connection

Power supply: AC220/50Hz(provided by the user to one side of the machine)

Air source used: 0.4-0.8Mpa(provided by the user to the machine side)

Operating temperature: -10℃ to 50℃

Basic conditions: A solid concrete floor with a flat suspending agent, and the thickness of the concrete should be greater than 10cm.

Optional models: Standard type and explosion-proof type filling