The automatic filling line has animation function and PID control function. The interface and operation process are customized according to different needs of users. Various operations can be carried out on the weighing filling system by clicking the touch screen. Filling ratio can be changed at any time, change the proportion of a material, the other proportion will automatically adjust according to their original proportion, to ensure that the total filling ratio is 100%, thus ensuring product quality and output.

020-34563445

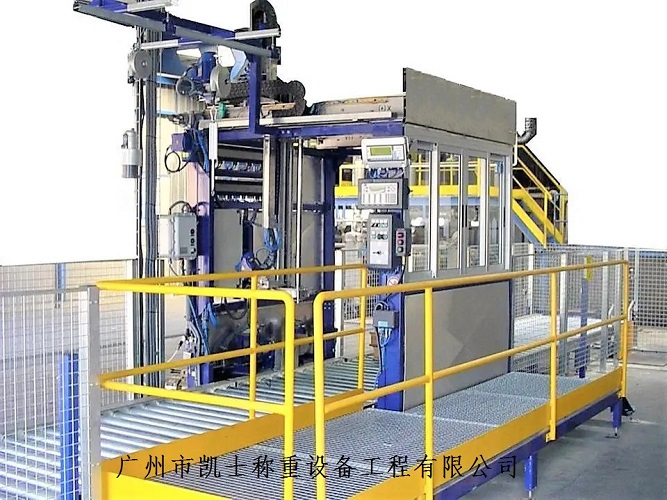

020-34563445Weighing Filling machine with animation function and PID control function, according to the different needs of users to customize the interface and operation process, by clicking the touch screen to carry out various operations on the weighing Filling system. Filling ratio can be changed at any time, change the proportion of a material, the other proportion will automatically adjust according to their original proportion, to ensure that the total filling ratio is 100%, thus ensuring product quality and output. In order to ensure data efficiency, the default data retention is time-driven, i.e. when the feed ratio is modified, when an alert occurs, or when other predefined events occur. The Weighing system also provides query of statistical data, such as yield reports. Data queries can be implemented not only locally, but also on any networked computer. Data queries are classified queries and do not require any additional software to be installed, just use an Internet browser. It is greatly convenient to use, so that the original data of production can be effectively applied, and the purpose of industrial informatization can be realized.

The Liquid filling machine is composed of main conveyor belt, defective conveyor belt, filling system, defective driving device, photoelectric sensor (positioning), weighing module, etc. Real-time monitoring of liquid filling machines, detected by sensors. The start and stop of the motor, the filling of the weighing system, the detection, pushing and counting of defective products are controlled by the PLC. The liquid first enters the high buffer tank at the valve station, the role of this high buffer tank is to ensure the supply of sufficient liquid to the ring cylinder of the filling machine and each filling valve under the condition of high speed filling. Before the empty tank enters the filling machine, it is cleaned with about 80 degrees of hot water through an S-shaped slide to ensure that the empty tank entering the filling machine is clean. There is a weighing module at the bottom of each filling valve. After filling, liquid of equal quantitative value is injected into the empty tank first. The weighing module measures the weight of the packaging container in real time and transmits it to the PLC control system. Then the control system reinjects the quantitative liquid into the filling valve for filling the next tank.