The weighing filling conveyor is responsible for the reading of the bar code of the filling barrel, the processing of the filling process and the display of information, and needs to transmit the filling record to the base station. The base station is responsible for receiving and forwarding the data, that is, putting the data received from the communication module onto the CAN bus, selecting the filling control function of the controller, the processor based on the ARM7TDMI-S kernel, and the peripherals such as USB controller and SPIIC UART interface can meet the requirements of filling and storage.

020-34563445

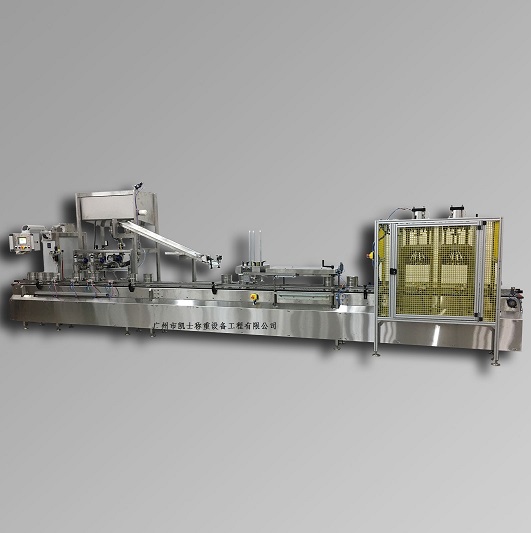

020-34563445The operation of the entire automatic Filling machine line only needs to press the start button, and the system will start to operate. The empty drums are first loaded onto a motorized roller conveyor and clamped. All the drums are stacked at the entrance of the roller conveyor. A double connecting rod makes the drums independent when entering the loading dock. The empty/full drum is pushed out/pulled in simultaneously, while the empty drum enters the loading table, another empty drum is pushed out of the table. When the barrel is on the loading platform, two electro-pneumatic controlled pull rods are pushed out against the surface of the barrel, while a third pull rod with a rubber wheel is also placed on the surface of the barrel. The third wheel is rotated by a motor, and when the barrel is in the right position, a sensor signals the presence of the lid and the drop of the barrel's stop rod. At the end of this rod is a pad that is fixed on one side and movable on the other.

First, when the cover is near the barrel, the rotation of the barrel is stopped, the motor is also stopped, and the movable part of the tie rod liner is closed. Then screw the lid pull rod over the barrel and lower the lid. Loosen the lid before putting it back on. Another mechanical rod, with a loading nozzle, is placed on the barrel and lowered into place. The nozzle enters the barrel, and all the components that hold it are returned and returned to the starting position for easy automation. Inside the nozzle, there are two solenoid valves to control the loading. The bucket is full and the weight is given by the display indicating the final weight. At the end of loading, the mechanical rod is raised and pulled out of the barrel, the stopper rod of the barrel is returned to the barrel, the liner on the side is closed, and the cap rod is screwed to tighten the cap. When these steps are complete, all tie rods are returned to the starting position. When the barrel is pushed out by the double rod, the roller conveyor that carries the full barrel is activated.

The drum is sent to the automatic drum stacker by the conveyor. Each time the drum approaches the stacker, the roller conveyor stops in front of the stacker and the drum is printed by the printing system. The bracket is placed on the stacker for loading. The normal state of the stacking machine is: loading on the right side, the pliers are on the top and open; The stacker detects when a full barrel appears, the pliers drop, and grip the barrel, then lift it up and haul it away. The motor stops, the pliers are lowered and opened to place the barrel on the carrier, and the truck enters the waiting state for the barrel. When the second bucket is detected, the above cycle is repeated, but the bucket is placed on the line and then entered the waiting state for the third bucket. At the end of the second bucket placement, the stacker moves forward to place the later bucket. After placing the first set of four drums, the stacker truck returns to its waiting position to fill the drums.