The quantitative filling conveyor uses the servo motor to control the stroke of the rotor pump, and then realizes the control of the filling amount. Before filling, the empty drum weight is obtained by the front weighing module, and after filling, the filling weight is obtained by the back weighing module and transmitted to the weighing instrument. The weighing instrument will calculate the filling data in real time to obtain the weight deviation. The filling gun will control the large material amount and send the control amount to the servo driver to drive the secondary filling valve to close the small material amount in advance.

020-34563445

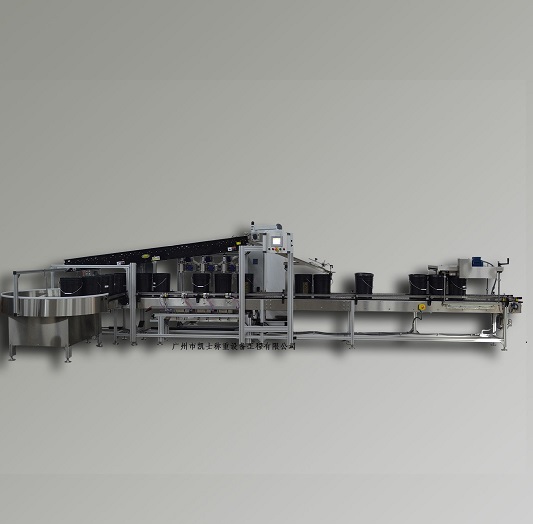

020-34563445The automatic Filling machine is an intelligent Filling system designed for liquid packaging in explosion-proof environment, which is used for the packaging of 200L drums (including pallets). The use of visual search can realize the automatic cover opening, automatic diving, automatic fast and slow filling, automatic leakage, automatic sealing screw cap and other processes of automatic packaging. The main part of the filling machine adopts environmental protection frame, can be Windows, automatic lifting and sliding door in and out of the barrel, and can form a closed space when filling. The electrical control part of the machine is composed of PLC programmable controller, weighing module, vision system, etc., which has strong control ability and high degree of automation. PLC with Ethernet communication interface, can communicate with the owner system. The machine has the functions of no barrel filling, no filling at the mouth of the barrel, avoiding the waste and pollution of materials, and making the mechanical and electrical integration of the machine get a good performance.

The weighing and filling machine adopts Kingview development monitoring system software PLC to collect input signals, and issues control orders to the filling mechanism after program processing. It uses open fieldbus and industrial Ethernet to achieve on-site information collection and system communication. The canning system adopts modern software architecture to manage, process, archive and establish documents for the project. The graphical configuration tools CFO and SFC established by international standards greatly simplify the configuration and maintenance of the system. With humanized man-machine interface, man-machine interface design with human operation habits as the design starting point, all modes have humanized operation interface, to provide convenience but also with a variety of protection functions, users can set personalized work parameters according to actual needs, after setting can be directly into the working state. The operation is simple and convenient, and there is no need to wait for complicated operations such as restart.