Explosion-proof tank scale is a new type of machine, which is controlled by PLC programmable device, which is set and measured by weighing sensor platform under the control of microcomputer program. Through the power track, the packaging barrel is accurately transported to the filling nozzle, reaching the filling target value, the filling head is automatically raised, and the two filling methods of net weight/gross weight are free to choose.

020-34563445

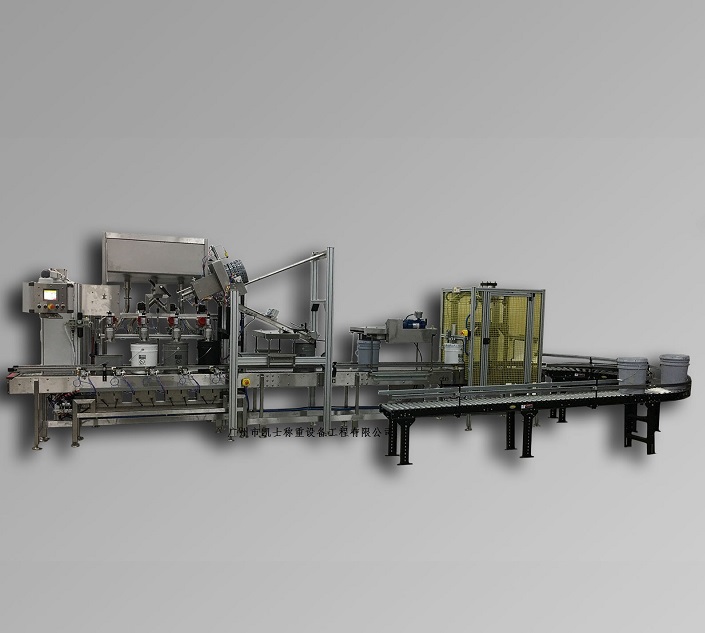

020-34563445Automatic Filling machine is a new type of machine, which is controlled by a PLC programmable device and is set by a weighing sensor platform under the control of a microcomputer program. Through the power track, the packaging barrel is accurately transported to the filling nozzle, reaching the filling target value, the filling head is automatically raised, the net weight/gross weight two filling methods can be freely selected, 30 groups of formula can be set and stored for calling, the filling target quantity is freely set, convenient for various weight packaging.

The weighing filling machine collects and processes weight data through communication, and sends peeling signals to peel the instrument. In the quantitative filling mode, PLC as the master receives the data from the weighing instrument, processes the data and sends out a series of signals to control the filling machine to complete the quantitative filling, and carries out real-time measurement and control on the place of the full barrel, stacking, lower cover, opening/closing the filling valve, etc. The PLC signal drives the motor and other transmission mechanisms to drive the manipulator to move, and at the same time drives the encoder with the motor to feedback the number of abusive pulses to the driver. The driver compares the two kinds of pulses and determines the deviation, and the correction signal obtained after calculating according to certain control laws is used as the given speed controller in the servo driver and then is adjusted by current and amplified by power. Make the grasping manipulator move in the direction of eliminating the deviation, so as to realize the stacking positioning of the manipulator.