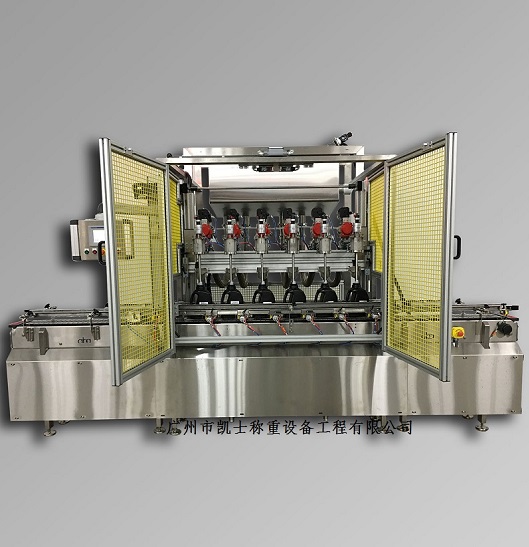

The automatic can machine adopts high-precision electronic scale combined with filling technology, so as to realize the metering and filling of liquid media. The weighing instrument and sensor have the functions of automatic peeling and automatic correction of the drop, and the whole process of automatic control such as metering, conveying, proportioning and mixing for various types of materials and liquids. The liquid filling machine is composed of a positioner program, a display program, a utility program, etc.

020-34563445

020-34563445The automatic Filling machine adopts high-precision Electronic scale combined with filling technology to realize the metering and filling of liquid media. The weighing instrument and weighing sensor have the functions of automatic peeling and automatic correction of the drop, and the whole process of automatic control such as metering, conveying, proportioning and mixing for various types of materials and liquids. The filling machine is composed of positioner program, display program, utility program start-up, etc.

After the system filling starts, the system carries out self-check, and ensures that the starting filling state is good through the processing and judgment of the input weighing module signal. When each Weighing system is ready, the host will call the memory formula to the starting filling area, and then start according to the corresponding formula supply. The host sends a control signal to start the filling corresponding to the main components of the first-level equation. The dosing module transmits the weight of the converted liquid to the dosing filling host through a certain functional relationship, and compares this data with the rapid collection, real-time processing of the host, and the setting of the corresponding components in the formulation. If the two are the same, the master will issue a control signal to control the stop filling. The same process is then used to fill the next part in the recipe to complete the batch ingredients until all ingredients have been completed.