Resin filling machine adopts double stroke double acting cylinder, cylinder with power filling head inside the valve stem for up and down movement, in order to achieve the opening and closing of the filling head. When the filling head opens the valve, the action is completed at one time, that is, under the lifting of the cylinder, the filling head valve stem walks up the entire design stroke, and begins to carry out the flow and fastest filling.

020-34563445

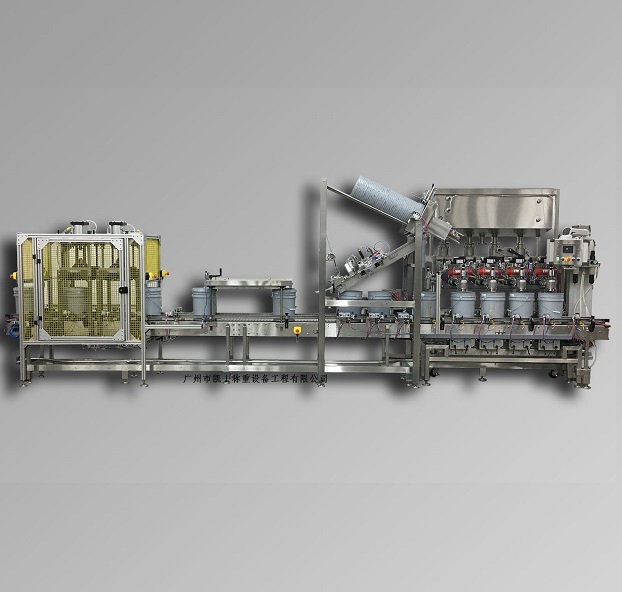

020-34563445Automatic Filling machine When the liquid level in the liquid storage tank is at or below the lower liquid level (lower limit value), the float pressure plate is separated from the mechanical valve and the pneumatic filling valve, and the liquid material is delivered to the liquid storage tank through the feed port. As the liquid level continues to rise, the float assembly rotates in the direction of the arrow, and when the liquid level in the liquid storage tank reaches the upper liquid level (upper limit value), The mechanical valve contact and the pneumatic filling valve are closed to stop conveying liquid materials to the liquid storage box. The Filling system is controlled by pneumatic valve, mechanical valve and pneumatic filling valve. The gas-controlled valve is normally open, and the mechanical valve and the pneumatic filling valve are normally closed. When the air source is opened, the air directly opens the pneumatic filling valve through the air control valve, and the liquid is transported to the liquid storage tank through the filling valve. When the liquid level in the liquid storage tank reaches the set maximum, the float pressure plate presses down the mechanical valve contact to replace the mechanical valve, and the pneumatic control valve is replaced through the mechanical valve to close the pneumatic filling valve, and the liquid is stopped to the liquid storage tank. With the filling process, the liquid level in the liquid storage tank continues to drop. When the liquid level in the liquid storage tank reaches the set minimum value, the pressure plate leaves the mechanical valve contact, the mechanical valve and the air control valve are reset under the action of the spring, the pneumatic filling valve is opened again, and the liquid is transported to the liquid storage tank again through the pneumatic filling valve. The cycle repeats.

The automatic filling machine uses a double-stroke double-acting cylinder, which moves up and down with the valve stem inside the filling head to realize the opening and closing of the filling head. When the filling head opens the valve, the action is completed at one time, that is, under the lifting of the cylinder, the filling head valve stem walks up the entire design stroke, and begins to carry out the flow and fastest filling. When the filling head closes the valve, the action is completed in two times. When the fast filling reaches the set value of the coarse close valve, the valve stem of the filling head first travels down a design stroke under the push of the cylinder, and begins to fill with small flow rate and slow speed; After a period of time, when the slow filling reaches the setting value of the fine closing valve, the valve stem of the filling head travels down for a period of design stroke under the push of the cylinder, and the filling head is closed, thus completing a filling.