The ethanol filling machine mainly collects the data of the weighing module, displays the data by the touch screen, accepts the data input of the potentiometer, controls the stable operation of the system through the control relay and the solenoid valve, and opens and opens the relay through the AD collection of the setting value of the filling. The pulse number of the sensor is collected by the motor operation and the filling quantity is displayed on the liquid crystal in real time. When the filling amount corresponding to the pulse number reaches the set value, turn off the relay to cut off the motor drive circuit.

020-34563445

020-34563445Automatic Filling machine adopts advanced man-machine interface operation, PLC control, variable frequency stepless speed regulation and other automatic control technology, with no bottle without cap, missing bottle waiting, card stop, cover chute without cap automatic stop and other functions. The suspension type bottle mouth conveyor structure is adopted to make the whole line conveying bottles more reliable. Different bottle types only need to adjust the conveyor belt height and a small number of change accessories, changing the bottle type is faster and less labor; Spring-type washing clamp, the empty bottle will automatically turn over 180° with the track to wash the inside of the bottle. The washing nozzle of the machine uses a plum hole to wash the bottom of the bottle at each Angle fully, and the washing efficiency is high. Screw cap machine adopts the technology of French company, screw cap head for magnetic torque screw cap, to achieve the grip cap, the grip cap process adopts two times to ensure the accuracy of the grip cap. The torque of the screw cap is stepless and adjustable, the torque of the screw cap is plastic, and the cap is not damaged, and the sealing is tight and reliable; The rotary cap trimmer adopts the pneumatic cap trimmer, which has the functions of not damaging the cover surface, sending the signal of missing cover in the hopper, and controlling the automatic replenishment of cover by the capping machine.

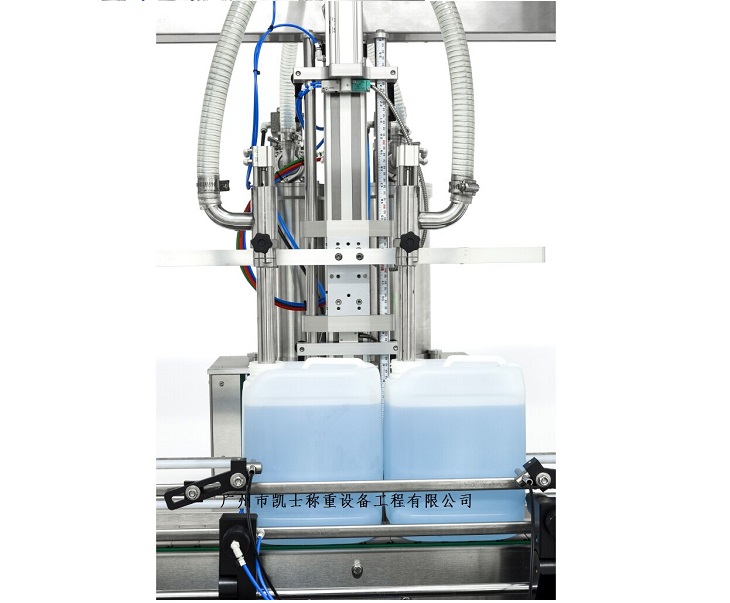

Weighing filling machine adopts vacuum pumping system to ensure no leakage, adopts automatic jack function, with automatic identification of empty drum tare range function and no bucket without filling function; It has the function of automatically detecting the overshoot of the filling target quantity, and can freely start the automatic correction function of the drop. After the automatic filling machine is opened, the conveyor starts to run, the main control system uses the main control element made by PLC, and the photoelectric input signal servo motor action cylinder is the output component. Automatic filling production online real-time monitoring, microprocessor through serial communication with PLC real-time data processing and data entry based on industrial computer and PLC precise control. The two-stage filling control equipment composed of fully intelligent upper computer industrial computer integrates mechanical and electrical signal processing and communication, and reasonably shares the tasks of upper monitoring and field data acquisition and control.