The coating filling machine is a filling equipment for automatic quantitative filling of liquid, and quantitative packaging of bulk liquid according to a predetermined weight. The liquid material transported by weight or power is automatically loaded into a number of standard empty barrels, and the material weight of each barrel is quantitatively controlled by opening and closing the valve.

020-34563445

020-34563445The automatic Filling machine adopts the latest microcomputer control technology of the United States, the weighing value is displayed in real time, 30 groups of formula can be set and stored, automatic alarm of excess, and replaceable discharge valve port. It has the function of automatically detecting the overshoot of the filling target quantity, and can freely start the automatic correction function of the drop; The controller is equipped with manual buttons for all actions and emergency stop buttons, which can store 30 sets of ink and paint filling parameters, and can only be called when in use; It has the functions of self-fault diagnosis, interface test, digital adjustment, anti-vibration setting and communication of host computer.

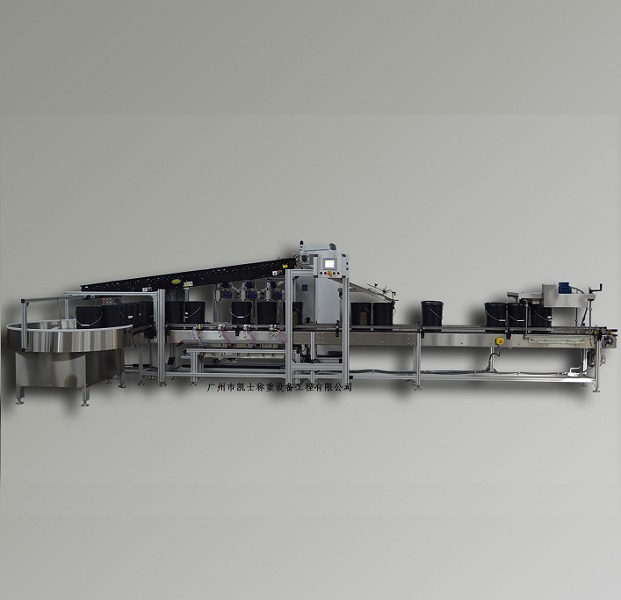

The Liquid filling machine is composed of computer, weighing module cabinet and peripheral filling equipment. The monitoring system is the man-machine interface of the whole system. One of the main stations completes all system parameter setting, process monitoring and data recording. The other as a slave station, based on the main station, in charge of post-filling data setting, process monitoring. The main station communicates directly with the Siemens S7300PLC, the filling valve and the rear weighing module. The front control system adopts a sealed junction box, dust and moisture proof, to ensure reliable signal transmission, and adopts a special industrial process controller to communicate with the central control room through RS485 bus, which can be independent control and PLC online control.

The Filling system has the functions of man-machine interaction, communication, display, storage, printing, etc., and has the function screen of data, graphic display, status monitoring, data input, information storage and other related operations. It can realize real-time process data monitoring, simulated display of process flow, real-time data record checking, operator authority setting, process parameter setting, event alarm setting during operation and manual and automatic control switching. Real-time display of flow, load, cumulative value, temperature, etc. The temperature indicator monitors the temperature range through the on-site filling liquid, and the pressure indicator displays the pressure inside the pump conveying liquid pipeline and the power current of the motor, and is transmitted to the central control room through the on-site weighing instrument for centralized display. The inverter adjusts the switch of the filling machine and communicates with the main control computer. The control unit is mainly weighing and batching instrument, PLC as an auxiliary control system, computer man-machine interface display filling parameters and monitoring and recording real-time data. In the automatic control mode, click the automatic "start" button in the filling process screen, or the "start" button in the front control cabinet, and the filling system will open the material valve according to the set filling amount. When the system detects that the filling valve is not closed, an alarm will occur and enter the suspended state. The feed valve speed of each Weighing system is provided with a lead amount. When the control instrument detects that the weight of the weighing material reaches the set value, the Electronic scale will subtract the lead amount, and the control weighing instrument will close the feed valve. The amount of lead can be manually corrected or automatically corrected, so that the control of each filling accuracy to reach the set target value.