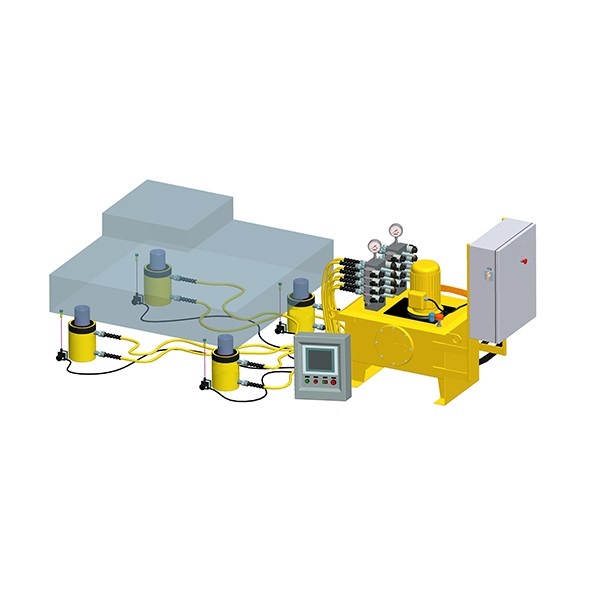

The hydraulic weighing device of offshore oil drilling platform adopts high-precision intelligent weighing hydraulic system, successfully replacing the traditional tilt test method in water, which can accurately calculate and verify whether the actual data conforms to the design. The whole work avoids offshore operation, and the platform can be loaded on the slide. The method can accurately measure the center of gravity coordinates and meet the strict requirement of center of gravity in Marine lifting operation. The whole system adopts PLC control, and the hydraulic jacks are synchronized. The lifting force is accurately measured in combination with the lifting search reference and the weighing module. Synchronization accuracy 1mm, weight accuracy 0.5%, meet the engineering requirements.

020-34563445

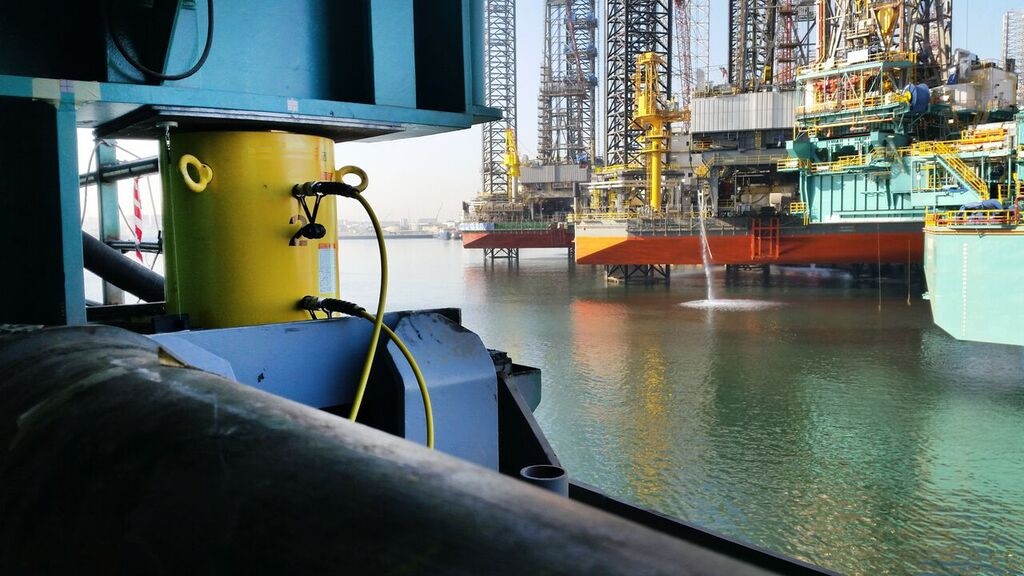

020-34563445Offshore oil RIGS often weigh thousands or even tens of thousands of tons. There is always a big difference between the theoretical weight and the actual weight, and the precise weight and center of gravity position of the platform need to be calculated in the construction work such as maritime transportation and installation, so after the equipment has completed its work, it is necessary to weigh the object and find the actual center of gravity position.

The calibration scale device adopts a high-precision intelligent weighing hydraulic system, successfully replacing the traditional tilt test method in water, which can accurately calculate and verify whether the actual data conforms to the design. The whole work avoids offshore operation, and the platform can be loaded on the slide. The method can accurately measure the center of gravity coordinates and meet the strict requirement of center of gravity in Marine lifting operation. The whole system adopts PLC control, and the hydraulic jacks are synchronized. The lifting force is accurately measured in combination with the lifting search reference and the weighing module. Synchronization accuracy 1mm, weight accuracy 0.5%, meet the engineering requirements.

Main functions:

1. Hydraulic Weighing system has the characteristics of high precision, simple operation, safety and reliability;

2. Modularity: flexible combination of operation console, hydraulic system, hydraulic weighing jack and sensor module;

3. Weighing module: high-precision weighing sensor;

4. Synchronous jacking: all fulcrum synchronous lifting, showing the total weight, point weight, center of gravity position, data output and report printing;

5. Quick connection of oil hose and cable: hydraulic system, hydraulic weighing jack, oil hose through quick connection; Weighing module and controller adopt aviation plug to realize fast connection of communication line;

6. Communication bus: The communication bus is used to connect the operating station, the hydraulic system and the field controller, and the aviation plug is used to achieve fast connection.

7. Operation interface: humanized design, with good human-machine friendly interface, simple and clear operation;

8. Measurement data: Weighing data can be stored, copied and printed.

Hydraulic weighing synchronous lifting system is a multi-functional hydraulic system controlled by PLC (programmable controller), lifting the load through the hydraulic jack (no additional auxiliary lifting equipment is required), the load weight is transferred to the hydraulic jack, and then detected by high-precision weighing sensor, through the design of the software calculation, the final weight can be reflected on the screen. And print out the data.