The servo weighing module uses the force source generator to simultaneously load the standard force meter and the tested force meter (including force and weighing sensors and weighing instruments). The two are connected in series and bear the same load. When the output of the force source generator reaches the calibration value of the standard force meter (calibrated with a higher-level force standard machine), the applied load is a standard force value. The force value is stabilized, and the output of the tested force meter is recorded. The loading and unloading are carried out step by step to complete the detection of the tested force meter.

020-34563445

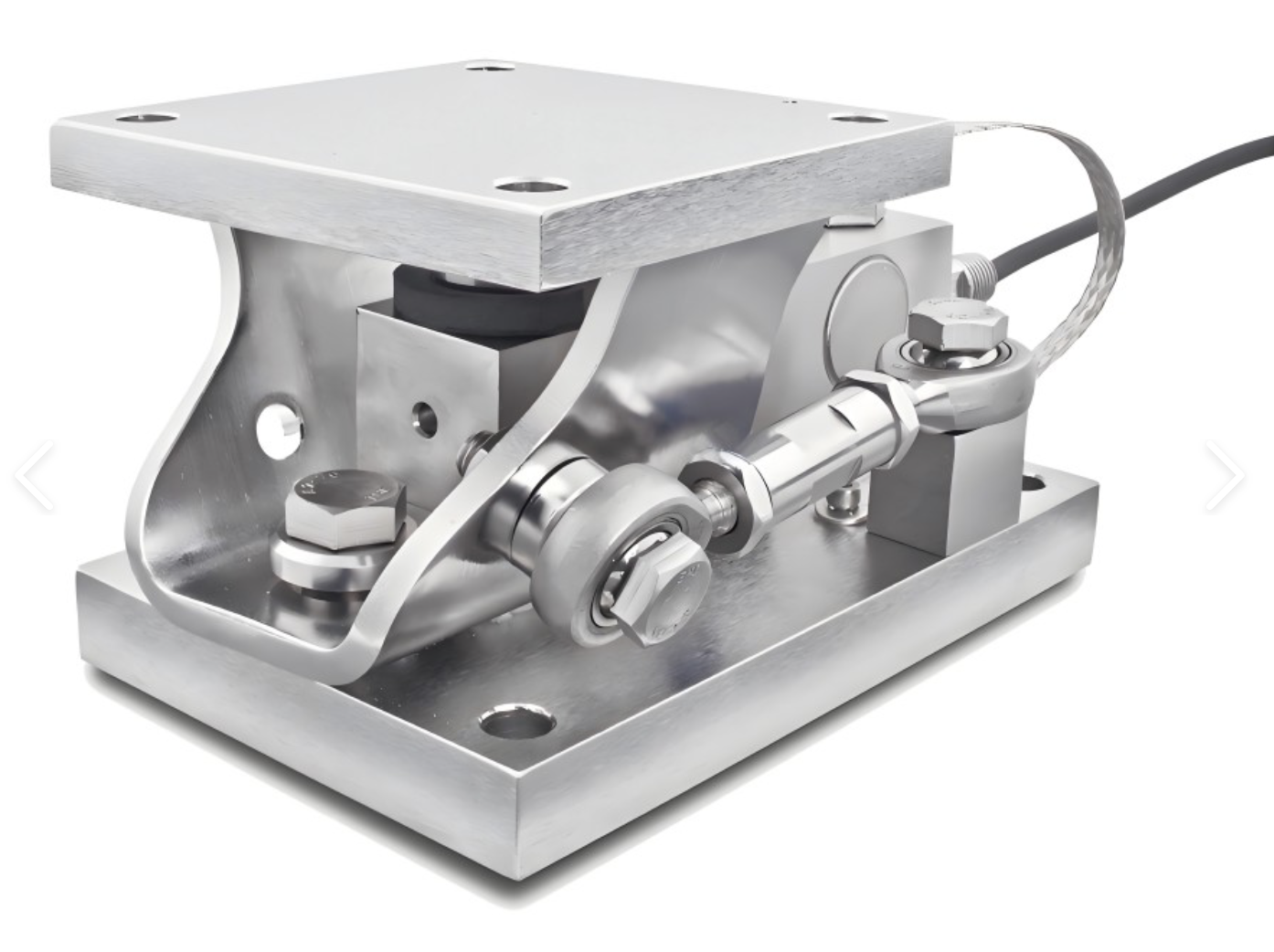

020-34563445The servo weighing module mainly consists of four parts: the standard weighing module force sensor, the hydraulic system, and the computer automatic control system. The standard force sensor is composed of a weighing sensor and a weighing instrument. The main unit is composed of a base, a crossbeam, a lifting motor, and a column section. The hydraulic system is composed of a hydraulic main cylinder, a working piston, an oil tank, valves, a large piston and its control motor, a small piston and its control motor. The computer system is composed of a main unit display and a controller, and is respectively connected to the tested weighing sensor and the weighing instrument.

The weighing module uses the force source generator to simultaneously load the standard force meter and the tested force meter (including force and weighing sensors and weighing instruments). The two are connected in series and bear the same load. When the output of the force source generator reaches the calibration value of the standard force meter (calibrated by a higher-level force standard machine), the applied load becomes a standard force value. The force value is stabilized, and the output of the tested force meter is recorded. The loading and unloading are carried out step by step to complete the detection of the tested force meter.

The weighing module is controlled by a microcomputer with electro-hydraulic servo system and combined with a two-level power control system. That is, the working large piston system serves as the main power part, while the small piston system acts as the fine-tuning control system. The microcomputer controls the servo motor to push the piston to achieve the process of pressure generation and stability of the weighing module. The force sensor of the weighing module and the force sensor being measured are connected in series. The power source adopts a two-level piston control system. The data is fed back to the control system through the data interface. The control system controls the rotational speed of the servo motor through algorithms, controls the piston feed, and regulates the system pressure.