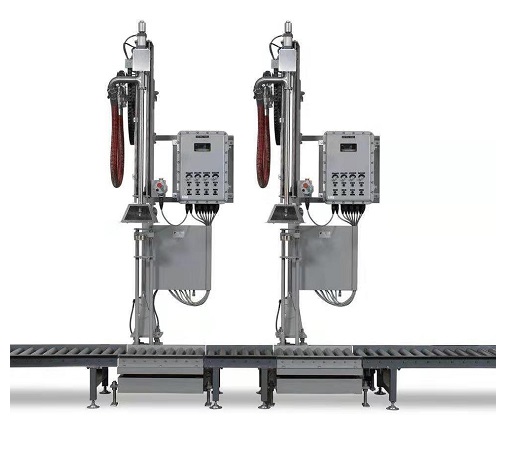

The Automatic metering filling machine controls intermittent container handling through timed feed screw, the feed screw can be set for multiple dosages to provide maximum production for large filling when running foam products. Adopting two-stage size material automatic filling method, with automatic judgment of empty barrel function and empty scale not filling function, double window display special filling control instrument, can display the target volume, filling volume, barrel number, time and date and other information, the controller can store 30 groups of filling value parameter, when using only call can be.

020-34563445

020-34563445When the automatic metering Filling machine's filling position detection device detects the in-situ detection signal of the pre-filled filling barrel, the conveyor belt pauses the transmission. After the motor of the main shaft lifting mechanism lowers the rotating main shaft of the bucket-taking mechanism to the position, the bucket-taking fixture clamps the pre-filled bucket. The conveyor belt starts to transport it to the fixed position. The bucket-taking rotating shaft conveys the filling bucket to the weighing detection platform. After the bucket-taking fixture releases the filling bucket into position, it conducts weight detection and then measures the weight and inputs the signal. Before filling, the bucket-taking fixture clamps the bucket. After filling is completed, the barrels are transferred to the conveyor belt. The barrel retrieval shaft rises to the position and rotates, and the weight detection action after filling is completed once.

The analog input module in the Filling system receives the measurement weight input signals of the barrels before filling and after filling, converts the measurement weight input signals into digital signals and inputs them into the system. The system compares it with the theoretical quality input signal, and in the filling system, calculates through the online automatic weight compensation model to obtain a quantitative output signal for correcting filling errors, and outputs a real-time detection weight signal. The real-time detection weight signal and the filling error output signal are displayed on the touch screen. The touch screen is capable of uploading production data (such as industrial capacity and production batch number) to the machine, and at the same time, it can check the instantaneous production rate, filling volume, etc.

The automatic filling machine adopts weighing instruments as the main control components, photoelectric and proximity switches and other detection Weighing modules as external input signals, and servo motors and action cylinders as output components. It has the functions of online real-time monitoring of products and inputting product information. The computer is connected to the weighing instrument through serial communication, which can collect data in real time, process it, input and save the data on the production line. The filling and packaging of barrels is completed in sequence through nine steps: barrel filling, barrel feeding, feeding, filling, barrel discharging, capping, box sealing, and stacking. During normal operation, when the interlock switch is closed and the external signals such as air pressure and liquid level conditions are met and normal, pressing the start switch will enter the automatic operation mode. Each workstation on the filling line should perform cyclic scanning according to the program programmed by the weighing instrument.

Technical parameters

Maximum weighing capacity: 300kg

Quantitative range: 100kg to 300kg

Graduation value: 100g

Filling accuracy: OIMLR61× (0.2)

Canning speed: 10 to 20 cans per hour

Power supply: AC220V50Hz

Operating air pressure: 0.5MPa

Control mode: 2-level control

Conveying method: The tank is conveyed manually. Valve material: SUS-304(optional: SUS-316)