Liquid canning machine adopts configuration software to monitor the interface design, can quickly component and generate the upper computer monitoring system, through the screen real-time display of the current filling quality, filling barrels and other field work status, the upper computer can carry out the corresponding operation, through the interface for the choice of filling mode and start, stop and other buttons operation. It can change the filling quality and number of barrels and manually remove the tare weight (i.e., the quality of the filling barrels) when using different filling barrels.

020-34563445

020-34563445The liquid Filling machine adopts Mitsubishi frequency converters, which are high-performance frequency converters based on flux vector control technology, pulse width modulation (PWM) principle and intelligent power modules. The main content of software design is the programming of PLC programmable controllers. To ensure the accurate and reliable operation of each part of the filling process, it is necessary to control each weighing module, relay, switch and solenoid valve through the PLC program.

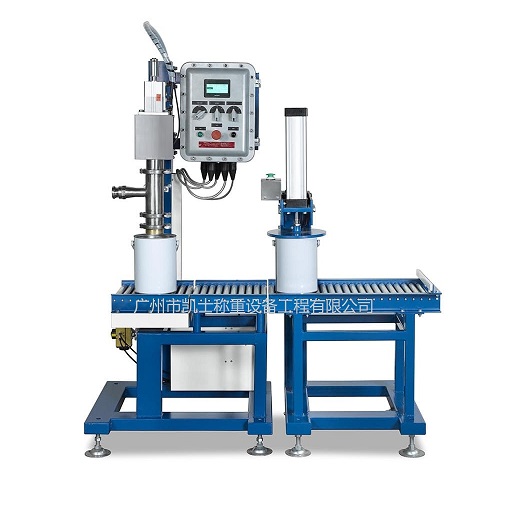

The Liquid filling machine is an automated filling equipment that automatically packages liquids. The liquid is filled into the target container to be packaged by gravity and then conveyed to the end by the conveyor belt. After that, it enters the filling and storage container. The first process is to clean the inner wall of the empty bottle. By opening the flushing mechanism through the solenoid valve, water is injected into the bottle under high pressure. After a certain delay, The rotary body motor rotates and enters the next station - the drying/disinfection station. The drying motor runs to dry the empty bottles and uses a high-temperature heater for disinfection. Then it enters the next station for automatic weighing and filling. Through gravity, the paste is filled into empty bottles. Then it enters the capping/labeling position. After the action is completed, it is removed from the line and enters the full bottle conveyor line, where it is conveyed to the end. The packing robot grabs it and packs the full bottle of paste into boxes. Thus, the processing of a bottle of paste is completed.

Basic parameters

Maximum weighing capacity: 30kg

Minimum sensitivity: 0.01kg

Filling error :±0.1-0.2kg

Filling speed: Approximately 150-180 barrels per hour for 20L

Control mode: 2-speed control

Filling method: Insertion type, liquid surface

Gun head tubing: Teflon gun head, valve + Teflon hose

Structural material: Main unit SUS304 stainless steel, conveying and palletizing carbon steel anti-corrosion paint.

Scale platform size: 400×800mm(304 stainless steel power raceway)

Empty barrel raceway :400mm×2500mm(304 stainless steel power raceway), with an additional 1200mm slope unpowered roller

Heavy barrel raceways :400mm×2500mm(304 stainless steel power raceways, 2 sets

Barrel separation device: Suitable for 200L barrels, carbon steel anti-corrosion paint structure, 304 stainless steel raceway.

Palletizing equipment: Translation-type, suitable for pallets of 1200×1200×140mm, including pallet, palletizing and lower pallet conveying.

Pipeline pressure: 0.2-0.6MPa(related to material properties).

Material interface: 4 DN40 flange joints, which can be customized according to the interface standards provided by the user

Air source interface: The user provides a 12mm air pipe connector for quick coupling connection

Power supply: AC220/50Hz(provided by the user to one side of the machine)

Air source used: 0.4-0.8Mpa(provided by the user to the machine side)

Operating temperature: -10℃ to 50℃

Basic conditions: A level and solid concrete floor with a concrete thickness greater than 10cm.

Optional models: Standard type, explosion-proof type filling scale