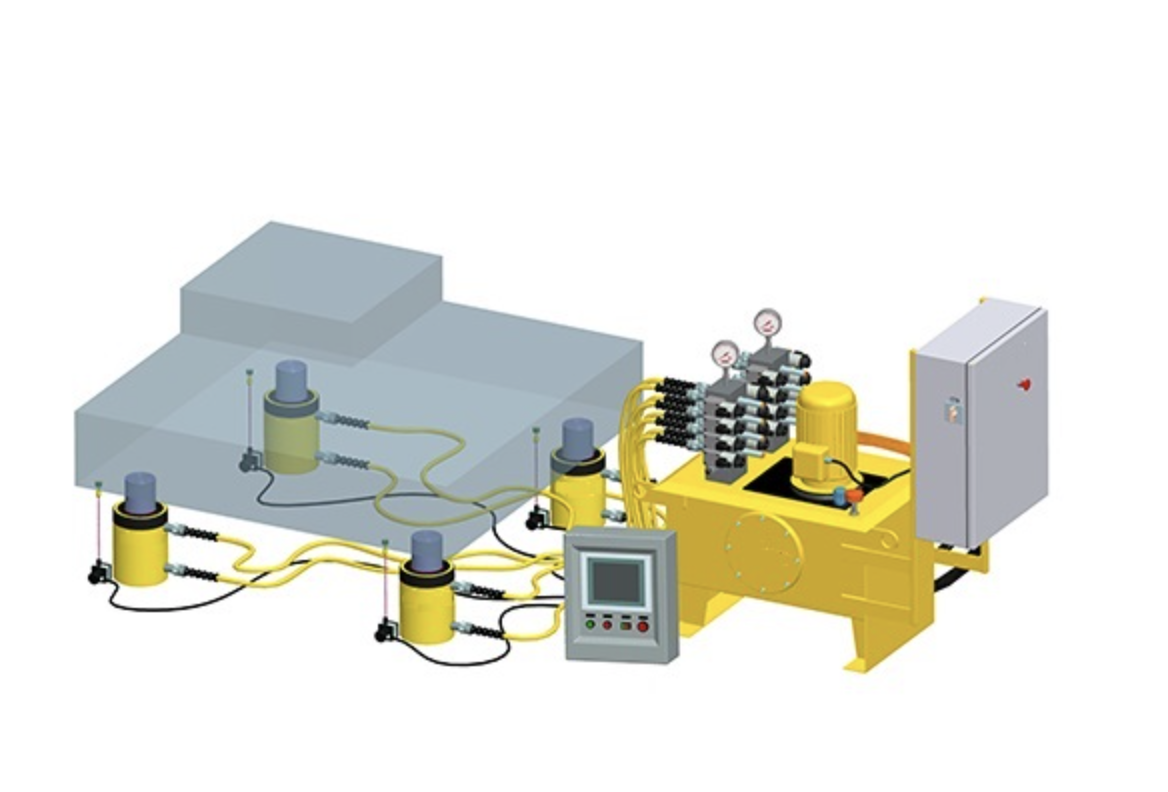

After the upper module of the offshore platform is completed on land, weighing module measurement operations need to be carried out to verify the weight center of gravity with the weighing module and ensure that the weight center of gravity of the upper module meets the requirements during hoisting at sea. The weighing module is a temporary component used for weighing operations and is a necessary condition for completing the weighing system.

020-34563445

020-34563445Most offshore platform projects adopt the method of building in blocks on land and hoisting the support points of the upper Weighing modules at sea to complete the overall closure. The accurate weight center of gravity plays a decisive role in the selection of floating cranes and slings. To avoid the deviation of the weight center of gravity affecting Marine hoisting, it is necessary to provide the weight center of gravity through the Weighing system design stage in the land stage and verify whether it meets the requirements of Marine hoisting. The weighing system uses multiple hydraulic jacks to synchronously lift the weighing module structure welded to the bottom of the upper module column. The weighing structure is a necessary condition for completing the weighing operation.

The weighing test of the cantilever beam assembly is divided into two parts: First, the drill platform is located at the longitudinal centerline position, and the total weight of the cantilever beam and the drill platform is calculated based on this weight. The second is that the drilling platform is located at a certain position on the starboard or starboard side, and the weight of the drilling platform itself (including the equipment inherent on the drilling platform) is calculated by weighing. A certain number of jacks are used to simultaneously lift the structure to be weighed off its support body, and the entire weight of the structure to be weighed is transferred to the jacks. The weight borne by each jack (i.e., the weight of each weighing point) is measured by the weighing module, and the total weight and the position of the center of gravity of the weighed structure are calculated through calculation. After the cantilever beam and the drill platform assembly are installed, their total weight is supported on the main deck by the cantilever beam. During weighing, the jack lifts the cantilever beam and the drill platform assembly as a whole by lifting the cantilever beam.