2025.05.06

2025.05.06Summary:The spiral batching system measures the transported materials by adjusting the relevant internal parameters of the PID. The frequency converter adjusts the speed of the upper feeder, so that the flow rate and stage accumulation of the materials are maintained within the set range and the measurement is completed. and ingredients.

0Introduction

China's animal husbandry, food, building materials, powder gold, rubber and pharmaceutical industries are developing rapidly, has been transformed from the rough to intensive, and the screw feeder with its feeding efficiency, precision and other advantages are widely used in the above industries, material transportation and measurement. Foreign research on the spiral feeder more, China has also begun to pay attention to the application of this area, research and development of related products. Data show that there is no measuring device and related institutions that can test and analyze the feeding accuracy and efficiency of the spiral feeder in China. This situation directly restricts the further development of the screw feeder and related industries. For this reason, a set of feeding efficiency and accuracy detection device is designed. The device can obtain the relevant data by changing the parameters such as feeding opening size, agitator pitch, rotational speed and lowering opening size. The final performance parameters of the screw feeder are obtained through the dosage machine, and after several sets of measurements are compared and analyzed to determine whether this screw feeder meets the relevant functional requirements. Measurement shows that the device has good practical value and practical significance.

1 working principle

The device can test the feeding accuracy and efficiency of the spiral feeding device by changing the feeding port size, stirrer pitch, speed and size of the mouth and other parameters of the measurement verification, and ultimately complete the accuracy and efficiency of the test to determine whether the stirrer meets the performance of its work, so as to lay the foundation for the research of the equipment.

The specific working process of the equipment is as follows: firstly, the initial value is written into the system; with the change of each parameter during the working process, the weighing module transmits the data to the data collection dosage machine through the communication port and displays it on the intelligent weighing instrument; finally, the dosage machine calculates the feeding accuracy and efficiency of the screw feeder, and after several sets of measurement for comparison and analysis, it is judged whether the screw feeder meets the relevant function or not. requirements.

2 overall program design

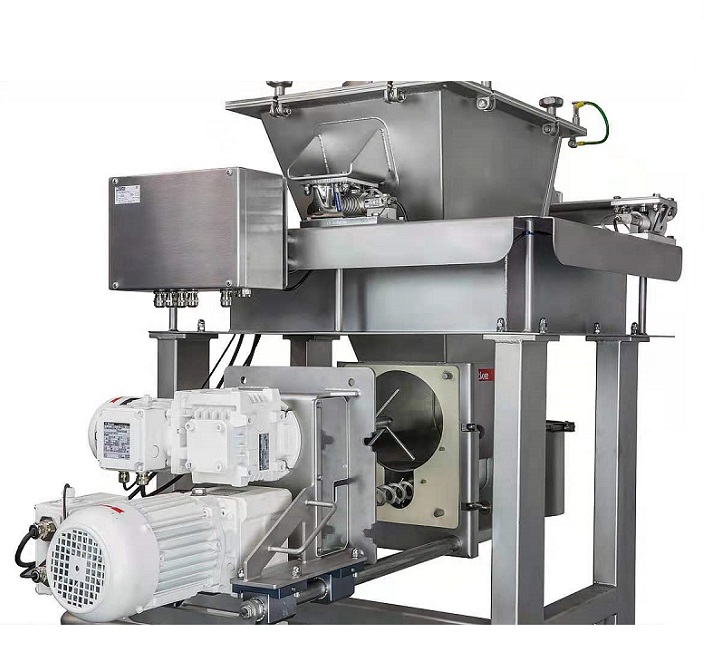

Bulk material spiral feeding and measuring table is mainly composed of frame, feeding system, data acquisition and batching machine, weighing system, control system and power system.

3 Related system design

3.1 Weighing system

Weighing is the key link in the work of this device. The weighing system adopts sensors, and the working principle is as follows: the mass of the weighed material is transferred from the scale body to the metering module, and the weighing module will have the output signals measured and processed by the weighing display and controller for signal measurement and processing, and then control the scale body in turn, so as to form a closed-loop measurement and control system in order to realize a complete weighing control system.

1) Sensor selection

Weighing module is a kind of conversion element that converts non-electrical quantity a mass into electrical quantity. The mass of the material in the weighing hopper can be transformed into an easy to measure and control the voltage, current, resistance or capacitance and other electrical quantities, is a lot of types of electronic sensors, in terms of its operating principle, there are resistance strain gauge type, capacitance, piezomagnetism and resonance type. The more widely used is the resistive strain gauge type sensor.

Resistive strain gage sensors are based on elastomers, the core of which is the strain gage. Resistive strain gage sensor elastomer structure form many common structural forms are cylindrical, side ring type, shear type, plate ring type, double ring type, pressure column type, pressure ring type, pull ring type and pressure shear type. This device is selected S-shaped weighing module, can withstand tensile or compressive force, good output symmetry, compact structure, easy to install, more specifications, is currently using more sensors for a variety of electromechanical secret hook scales and hopper scales.

2) Sensor range setting of the weighing system, the closer the weighing value is to the rated range of the sensor, the higher its weighing accuracy.

3)The selection of intelligent weighing instrument selects SM40H fixed value and dosage controller.

structural design; secondly, excellent weighing and batching function; thirdly, safe and reliable control interface; fourthly, powerful communication ability; fifthly, rich accessory function.

3.2 Information Acquisition and Batching Machine Information Acquisition and Batching Machine is the core system for the work of this device. The Information Acquisition and Batching Machine integrates VB programming technology, microcontroller technology and sensor technology, etc. By taking the size of the feeding port, the pitch of the agitator, the rotating speed and the size of the lower feeding port as variable factors, one of them is taken as a variable factor in collecting the metering data, and the other parameters are written as quantitative to the system. The weighing system transmits the actual discharging quantity to the batching machine through the communication port, and through the timer of this system, the theoretical discharging quantity, precision and efficiency can be calculated, and then all the information is transmitted to the database, and the metering data is processed to judge whether this screw feeder meets the relevant functional requirements. By using this system, the accuracy of data collection is greatly improved, the influence of human factors is reduced, the reliability of the device is improved, and the working performance of the device is more stable.

3.3 Bulk material screw feeding feeding system Bulk material screw feeding metering table feeding system in the core component is the spiral churn, which is also the main object of the device inspection, directly affecting the efficiency and accuracy of feeding. Its main dimensions are hollow shaft outer diameter, inner diameter, spiral blade diameter, pitch, length and blade thickness.

The structural dimensions of the spiral body to ensure that there is enough strength, stiffness, but also to ensure that there is enough conveying capacity and small power consumption, so the spiral body blade diameter, blade pitch, shaft tube outer diameter, shaft tube inner diameter, length and blade thickness there is an optimal combination of issues. Among them, the length of the spiral body, blade thickness according to the structural requirements can be set as a constant, the machine needs to determine the design parameters, identified as the optimization of design variables.

3.4 Selection of the power system of the spiral feeding metering table for bulk materials In order to meet the requirements of the churn rotation (such as high rotation accuracy, the ability to stop in time, smooth operation, low vibration, easy to adjust and can not cause harm to the human body), the power selected is BYG stepper motor. Motor.

3.5 Motor technical data

The above data can meet the requirements of the device power, and this motor is light in quality, easy to use and low noise.

4 Conclusion

1)The dosing device takes computer as the information entry port and microcontroller as the data processing and control sub-stage, which can well complete the detection of the accuracy and efficiency of the spiral feeder.

2)The weighing system adopted by the device utilizes sensors to convert the non-electrical mass into electrical signals, which are directly transmitted to the batching machine to reduce the influence of human factors and improve the accuracy of the data.

3) The device takes the feeding port size parameter, churn pitch parameter, rotational speed parameter and the size parameter of the lower feeding port as variables, which can comprehensively examine the influencing factors of the working performance of the screw feeder, thus laying a good foundation for the optimized design of the screw feeder.