2022.09.26

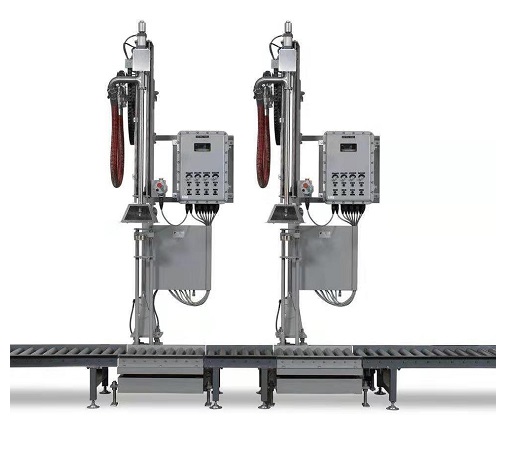

2022.09.26Summary:The automatic filling machine is a highly automated packaging equipment. It takes advantage of the high measurement accuracy of electronic scales to connect the electronic scale signal sensor and the weighing control instrument with a data line.

The filling system adopts microcomputer technology, through the RS485 interface, ModbusRTU protocol communication ARM control system, can realize the automatic switching of self-flow mode and pump filling mode, the setting of the weight parameters, the use of the weight of intelligent judgment, can realize the pump filling liquid operation state, automatically realize the start-stop control of the filling system, and complete the accurate measurement of the filling volume, display, settlement, printing and other functions, the pressure, weight, temperature and other factors, the weight indicator control stop the pump, close the pneumatic valve. The setting of upper and lower limits of parameters such as pressure, weight, temperature, etc. realizes the function of emergency cut-off under the abnormal state of the filling pipeline, which effectively avoids the occurrence of accidents. It can realize the functions of inquiry and automatic totalization of the number of times of liquid filling, liquid filling quantity and liquid filling amount. The cylinder actuator can be used for the overall coordinated control of barrel positioning, roller conveyor operation, weighing and filling, and trough materials. Adopting man-machine interface for manual, automatic and other modes of control, eliminating a large number of buttons, switches and other devices on the panel, which is convenient for operation; at the same time, there are a lot of status displays on the touch screen, which is convenient for the operator to understand the system's operating status. High-precision metering module and high-stability weighing instrument are selected to control the filling process, which fully meet the accuracy and speed requirements of the canning system.

Liquid filling machine adopts the configuration king to develop the monitoring system software PLC is responsible for collecting input signals, after the program processing, sends out the control command to the filling mechanism, uses the open field bus and industrial Ethernet to realize the field information collection and system communication, the canning system adopts the modernized software system structure, manages, handles, archives and establishes the documents for the project. The graphic configuration tools CFO and SFC established by IEC-1131 international standard greatly simplify the system configuration and maintenance. With humanized human-machine interface, the human-machine interface is designed with human operating habits as the starting point, and various modes are equipped with humanized operating interfaces to provide convenience and various protection functions, and users can set personalized working parameters according to their actual needs, and they can enter the working state directly after setting. Simple and convenient operation, no need to wait for restart and other complex operations.